About us

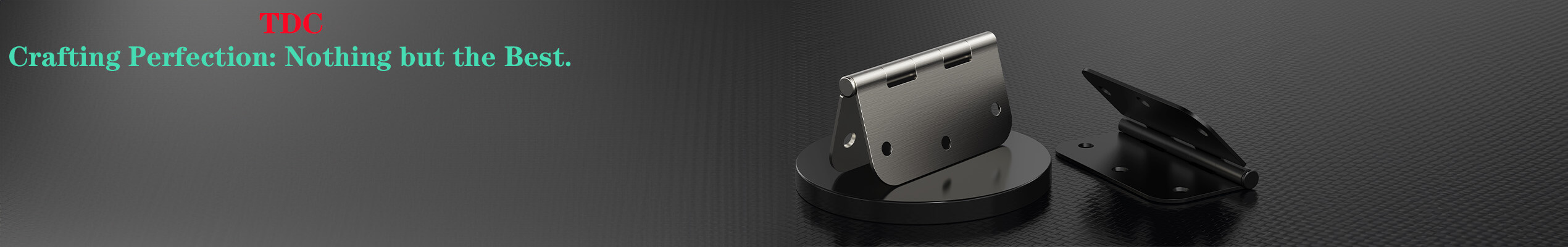

- Tendency(TDC) is a leading manufacturer of hinges and has been since the company was founded. We are committed to providing innovative products that meet the needs of our customers, from retailers to distributors to end users.

- When it comes to hinges, you deserve to work with the most knowledgeable and experienced experts in the industry. At TDC, we take pride in being recognized as the foremost hinge experts, delivering unparalleled products and solutions for all your hinge-related needs.

Our mission is simple:

- to offer sincere pricing and deliver quality products from the heart.

- At TDC, we believe that hinges are more than just the hardware you need to fasten a door. They're a key part of your brand identity, and they should reflect your company's values and aesthetic.

- We want to help you find the perfect hinge for every application so you can make sure all of your doors look great. We know that hinges come in all shapes, sizes, and materials—and we have them all! Our goal is to help you find the perfect hinge for every situation, so you can get back to running your business faster.

- TDCHINGES is a leading manufacturer and distributor specializing in durable, high-quality hinges. We are committed to making sure that our products are easy to install, help save space, and offer an aesthetic appeal.

- We believe that everyone deserves reliable products that look good and last a long time. That's why we strive to create products that are durable but still aesthetically pleasing. We also aim for our products to be easy to use, so installation is simple enough for even the most inexperienced DIYers.

- Our mission is to provide homeowners with quality products that they can use for years without having to worry about them breaking down or not fitting into their home decor.

- Our goal is for every customer—whether they're a retailer or an end user—to feel like they made the right choice when they chose TDC.

We are TENDENCY-HARDWARE.

- We started this company because we love hinges. We know that you love hinges, too. Hinges are an integral part of the world around us, and we're here to make sure that when your customers are shopping for new hinges, they can get exactly what they want. Hinges are our passion and specialty. We possess an in-depth understanding of hinge mechanisms, materials, functionality, and design principles. Our experts stay up to date with the latest industry trends and innovations, ensuring that we offer you cutting-edge hinge solutions tailored to your unique requirements.

- We manufacture and are able to offer a wide variety of quality products from some of the most trusted manufacturers in the industry. Whether you're looking for something simple or something complex, we've got what you need! Your satisfaction is our utmost priority. We believe in building strong relationships with our clients based on trust, communication, and exceptional service. Our team is dedicated to understanding your specific needs and providing personalized support and guidance throughout the entire hinge process, ensuring your complete satisfaction. Our experienced staff is always ready to help if you have any questions or concerns about our products or services—just give us a call at +86-573-85845364 or email us at milly@tdc-hardware.com